Real Time Well Testing

Whether you are comfortably sitting on your sofa at home or in the office onshore, you can have access to all the well testing data on a real-time basis during the operations, as if you were in the TDA cabin offshore.

Pressure and temperature sensors are installed upstream and downstream of each equipment in the surface well testing facilities. In the wellbore, wireless acoustic pressure gauges are positioned mid tubing, above the downhole shut-in tool and below. Thanks to Metrol DTA, you may even have some distributed temperature surveys inside the perforating guns, giving you a real-time temperature profile along the perforations. A software can then help you in collecting and visualizing the data.

Why going real-time ?

Real time well testing helps to monitor all the data and trends as the operations unfold. This is used to make real-time decisions, to ensure safe operations, to quality check and validate the data, and to optimize the operations, leading to less flaring and lower cost. New well testing tools and techniques on these real-time data will help to bring a better understanding of the operations and of the well and reservoir.

Looking at the live well test data from the office

Safety

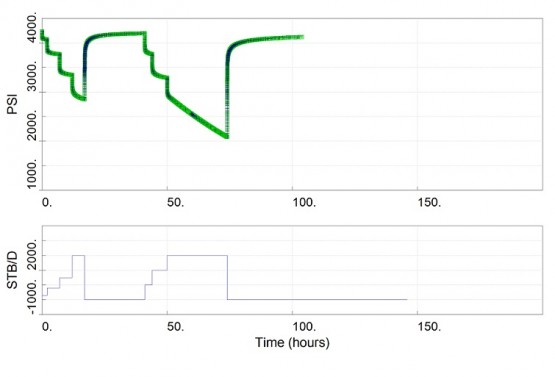

With a fit-for-purpose DST string, with multiple real-time gauges in the tubing, the operator can spot the different types of fluids coming up in the well and understand better the operations. For example, the presence of gas could be detected in the wellbore, before reaching surface. The multiple real-time gauges will also help when killing the well at the end of the operations.

You may be in the middle of the rig monitoring the separator, the TDA may be busy setting up the new orifice plate, filling up the report or answering questions from an upset operator. The fact is, in the middle of some well testing operations, we may not have our eyes everywhere, we may not watch all the trends, spot something abnormal or understand a particular change. This can be a stressful environment and our capabilities might be limited.

Real-time well testing will allow the ops well test specialists onshore to monitor the trends and spot anything that doesn’t make sense. Having access to real-time information will also improve communication between the offshore and onshore teams.

This system can bring much more value, if properly used.

Quality check and validate the data

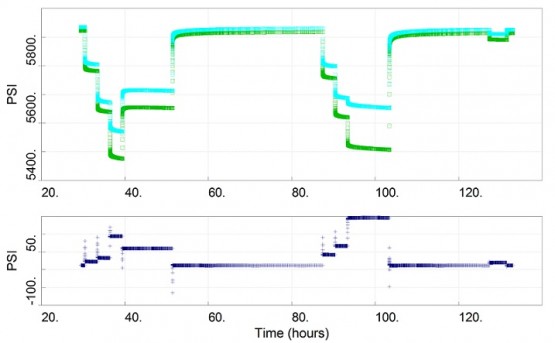

During the operations, the multiple gauges could be compared, as shown in the figure below.

Gauge Comparison showing pressure data from two gauges and its difference ΔP.

This will help to quality check the data, understand any wellbore dynamic effect and monitor the integrity of the downhole shut-in valve. This will improve the understanding of the test, ultimately leading to better quality data.

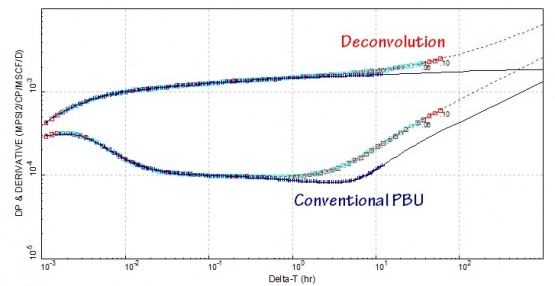

By plotting several PBUs on the same log-log plot, the rate data could also be quality checked.

Achieve the subsurface objectives with an optimum test

A downhole memory gauge may not properly record the data, the sampling rate may not be suitable or the gauge may simply fail without the operator knowing it. The operator may end up with a test that is too short and doesn’t contain enough information to achieve the subsurface objectives. In this case, the entire well test will be a failure.

For saving some few percent on the budget by not running some real-time pressure gauges, we risk to compromise the entire well test and the total cost, up to tens of millions.

Or the test may be too long, with the operator spending much more money than what a simple real-time system would have costed. Some huge savings up to millions could be made with a simple real-time downhole system.

Wireless downhole gauges and real-time analysis with the latest techniques and technology will help the operator to make real-time decisions and optimize the test. Costs and flaring will be minimized.

Optimize the well test operations and PBU duration

Opportunities to increase value at lower cost

After safety, the aim should be to acquire the best quality data to achieve the subsurface objectives but also to look for opportunities to obtain any extra valuable information at low cost.

To be able to make a real-time decision based on real-time data, the operator needs to have some expertise in well test analysis and perform some real-time analysis. The purpose is not to perform a final interpretation but to investigate multiple scenarios, make sure that we achieve the objectives, reduce the non-uniqueness and investigate opportunities to learn more. Real-time deconvolution could be used to obtain more value while reducing the test sequence and improving the understanding of the test.

For an exploration and appraisal well test, there is only one chance to acquire the data. During the operations, we may learn some new information and we should then be adaptable and the test flexible to investigate a particular scenario. Opportunities to acquire more valuable data at lower cost could be chased.

A double-edged sword

There is a risk of expediting the decision-making process based on a wrong understanding or interpretation. As a result, the operations could be terminated sooner, compromising the entire well test, or last longer wasting time and money. With real-time data, under time and cost constraints, the analyst may not fully investigate all the possible scenarios and may not fully understand the test.

There is a risk that under stress, under demands for results, only a partial analysis is performed and some important solutions are skipped. Something may be missed and the operator will take a decision based on a misinterpretation or misunderstanding.

The operator or service company needs some expertise and a bit of patience. A general rule could be that it is always better to have slightly more than less.

A minimum shut-in duration could also be set to 12-24 hrs, to avoid taking rash decisions based on real-time data.

With emotions, the analyst may not be objective but a bit biased, looking only at the upside cases.

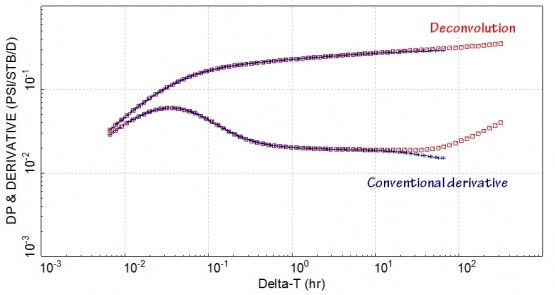

Looking for example at the response below, do we see some good news (an improvement in the reservoir properties) or some bad news (boundaries) ? Guess what the team assumed during this appraisal well test…

Real-time deconvolution supports the presence of boundaries

In the figure above, the reliable Deconvolution drives the analysis and clearly shows the presence of boundary. The downturn in the conventional derivative is a distortion, an error created by the derivative calculation algorithm. At that stage, there is no point in extending the shut-in.

Be prepared for real-time well testing

When it goes “live” during the operations, the analyst needs to be prepared to quickly react to the data. This will help to minimize any error in interpretation and to avoid a wrong decision.

A full design study looking at all possible cases and what-if scenarios will help to be better prepared during the operations, have a range of expected responses and end up with a successful well test. The analyst who performs the well test design and defines the rate schedule should be the one looking at the real-time analysis. This is part of the integrated well testing services, from design to post-operations interpretation.

The real-time analysis should not be definitive. It should only be there to guide and take the right decision. A proper and exhaustive post-operations well test interpretation should be performed later on when all the final data and sample analysis are available. The well test data should then be integrated with other sources of subsurface information.

Minimum equipments and setting for real-time well testing

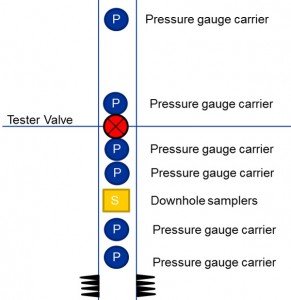

Real-time wireless gauges should be positioned at several strategic locations in the tubing. If the well completion is not fit-for-purpose, if the real-time gauges are not well placed then real time well testing will not be efficient. Worse, the entire well test might be compromised.

We also need to check that the sampling rate is properly selected before each PBU test.

DST Equipments for E&A Well Testing

It is critical to understand the changes in fluid density and gradient during the pressure build-up tests thanks to the multiple gauges. This is the only way to quality check the pressure data below the downhole shut-in tool and it could also support the PVT data. If the fluid gradient changes, with a liquid/gas interface, we want to know where the interface is and which gauges to use for PBU analysis.

In addition to memory gauges, the real-time Metrol gauges are recommended. The Metrol system is fast, reliable and accurate, as demonstrated over 10+ years in the industry.

Lately, Schlumberger came up with a similar acoustic wireless system called Muzic. However, this system is still at an early stage and cannot deliver real-time data from multiple gauges with high sampling rate.

Quiz

Let’s assume we are in the middle of an exploration and appraisal well test and we performed a second PBU test 12 hours ago, with the real-time derivative plot below. Would you terminate the test ?

Click on the button below to start the exercise.

get ready