Minimize rig time and flared volume

Some special efforts in well test design and operations can be pursued to minimize rig time and minimize the flared volume. Flaring less volume and for a lower amount of time is not only good for safety and environmental reasons, but also cost effective.

However, any effort to minimize rig time and flared volume should not compromise the quality of the data and the reservoir subsurface objectives. We should stay flexible and look for any extra value-adding opportunities at minimum cost.

Most of the well tests are still designed and performed with some old techniques in mind. These techniques can clearly be challenged when applying the latest tools (deconvolution, new pressure gauges, etc…) and techniques.

Pressure gauges:

We no longer need to withdraw large amount of reservoir fluid thanks to improved technology with quartz pressure gauges. Gauge noise and resolution are so small that we don’t need to flare as much to detect and collect small pressure changes during the PBUs. However, we still tend to design our test assuming old-fashioned mechanical gauges…

Design the flowing time and flared volume based on a certain level of depletion:

We tend to design well tests assuming a certain level of depletion ∆P, which will be created from flaring an hydrocarbon volume ∆V. We need to produce enough hydrocarbon to “make a dent” in the reservoir and obtain a level of depletion ∆P greater than the measurement error and any possible fluid density change.

Total compressibility can be written as Ct= ∆V / (V.∆P). Then we should flare an hydrocarbon volume:

∆V = Ct.∆P.V

with ∆V the flared volume, ∆P the level of depletion (usually a couple of psi) and V the volume we want to prove.

This technique is based on a certain volume to prove and may not apply for some well tests whose objective is not to investigate reservoir connectivity. In addition, it depends on the depletion ∆P, which might be difficult to recover with the actual test data, under transient period.

This flared volume should be seen as a sort of maximum flared volume.

We could help to challenge this design with new well testing techniques using the conventional and deconvolved derivative.

Guidelines on Design and Operations to achieve objectives and optimise the test

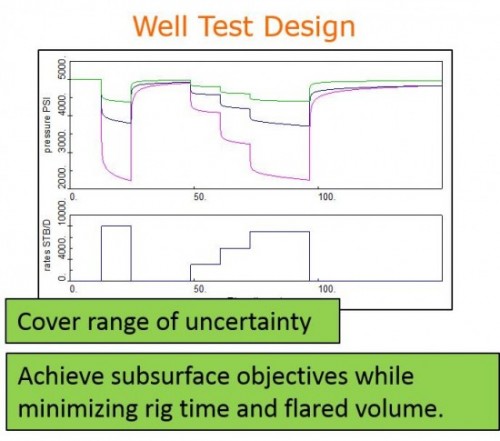

To decide on the duration of flow periods and PBUs, we must perform a design study using a well test software. In TestWells, we will be happy to do that for you.

The well test should be designed considering a large range of reservoir and fluid properties, with particular attention to the very worst case scenario. If investigating reservoir connectivity is part of the well test objectives, then the conventional derivative should be used for this matter in the design study.

This should result in some conservative test duration with a minimum of 2 PBU tests, which should be agreed with management.

In operations, with real-time learning and a plan-do-measure-learn process in place, the test can be managed to include any extra value at minimum cost and optimised using well testing tools and techniques (real-time deconvolution and analysis).

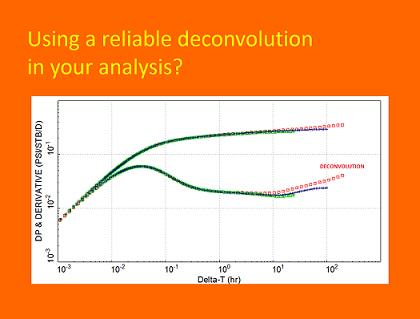

Shut-in duration would be dictated by cost constraints and by some target value of the radius of investigation. However, with access to real-time data, and provided 2 PBU tests, deconvolution can be investigated and used to shorten the 2nd PBU test.

It is worth noting that the shut-in duration needs to be long enough to see past the wellbore storage effect and to contain enough information for deconvolution to work.

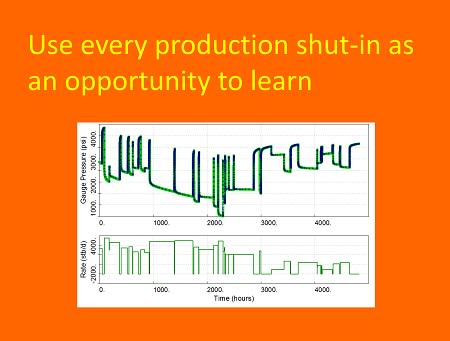

The same design and analysis techniques can be applied on production wells.

Let us share with you some few other tips:

Removing the deliverability test

While this type of test is still recommended by some companies, the only deliverability test that we see as worth doing is the flow-after-flow test, i.e. step changes in rate for gas wells to define the turbulence factor D in d/Mscf.

There shouldn’t be any need for other fancy deliverability tests, especially when a PBU analysis gives us all we need, i.e. permeability, skin, initial pressure, connected volume, etc…

If you don’t agree with us, we will be more than happy to discuss it with you.

Removing the initial flow and shut-in after perforation and before clean-up:

Initial flow that produces a very small volume followed by an initial shut-in could be removed from the test.

The main objective with this old technique is to obtain an initial pressure value. At this stage, the well hasn’t been cleaned up and some uncertainty remains on the fluid density below the gauge (especially after a very small drawdown).

As a result, the initial pressure value derived from this technique is associated with a large range of uncertainty, and probably won’t be too useful for pressure transient analysis (in some cases, the result may vary by more than 100 psi from the correct initial pressure).

Nowadays, a good estimate of initial pressure value can be obtained with MDT data and/or refined with deconvolution, provided 2 PBU tests.

Again, if you disagree, let’s chat !

For more information, please select one of the links below. Or simply contact us.

Quicklook review of design or analysis

Simply send us your presentation or report via the

Secure File Transfer.

We will send you our comments, explain what could be missing, improved or better explained, and what other solutions are possible.

For a more detailed analysis, please send us more data. Check out the Input Needed.

Get the most out of your data !

Join the Well Testing Group

Place where members can learn, share case studies & best practices and challenge each other.

Receive information on well test design and analysis and join-in to audio teleconference sessions.

Get access to more resources, ideas and help with our library.

Why testing wells ?

Exploration, appraisal, development

- Confirmation of discovery and productivity

- Clean-up and rate measurement

- Large volume fluid sample

- Well and reservoir performance

- (skin, KH, Pi, heterogeneity, boundaries)

- Reservoir connectivity & proven volume

- Flow behaviour around wellbore

- Large scale of investigation (100-1000s ft)

Production and injection

- Use of opportunistic shut-ins

- Track permeability, skin, reservoir pressure

- Monitor performance over time

- Understand performance deviation

- Assess well intervention

- Quality control rate measurement

No alternative

No other alternative to:

-

obtain large fluid sample

-

evaluate permeability over large distances (~100s-1000s feet),

-

assess well damage (skin)

-

investigate connectivity over large volume

Why using our services?

Global Experience from Explo to Production

Extensive experience from Exploration to Production, in all types of wells and reservoirs worldwide, in particular North Sea (UK and Norwegian sectors), GoM, Brasil, Azerbaijan, Algeria, Angola, Canada, Egypt, Oman, Jordan, Indonesia, etc…

Expertise in deconvolution

We have expertise in deconvolution.

Deconvolution is a great asset for your team. It helps to improve the understanding of the pressure data, refine initial pressure and add reservoir insights. While deconvolution is not new, it is often misused in the industry.

We are also dedicated to coaching you with deconvolution.

Dedicated to you !

We can act as your team well test expert, provide a 2nd review or simply reduce your expert’s workload.

We can review data from your shut-in or active wells with or without downhole gauges.

Maximum value

With costly and rare shut-in pressure data, don’t compromise on its interpretation.

We guarantee to provide more value out of your data. Let’s try a quick review of your existing design or interpretation and we’ll send you our comments.

Get a 2nd opinion

You already have a design or interpretation study but are not entirely satisfied or simply want to check if more value can be obtained at minimum cost?

Get a second review from us.

Our clients

We support geologists, petrophysicists, engineers from national companies, independents, majors and more “generalist” service companies.