Production Flow Test or Well Test ?

In the North Sea, it is very common to call a production flow test a “well test”.

In a production flow test, the well is flowed through a test separator or a multiphase flow meter MPFM. An average measured rate is reported, along with wellhead and bottom-hole pressure values. In theory, flow stability and pseudo-steady state should be achieved during this flow test but this is often not the case, in practice.

Sometimes, the operator tests “by difference”, meaning that it will shut one well and measure the difference in total rate. This is not recommended.

Then this “well test” is used to calibrate the well files, updating the inflow performance relationship (IPR) and the tubing performance. These files will then be used for rate allocation and surveillance, to monitor the well performance over time.

Just to be clear, this is not a “well test”, but a production flow test.

Well Test and PBU test

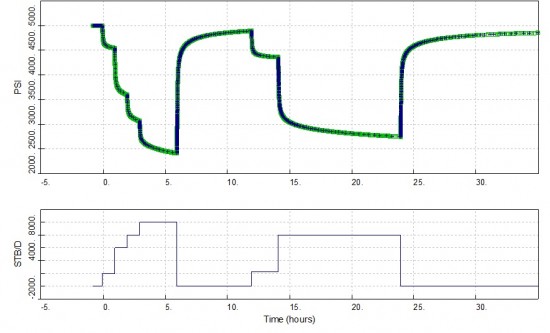

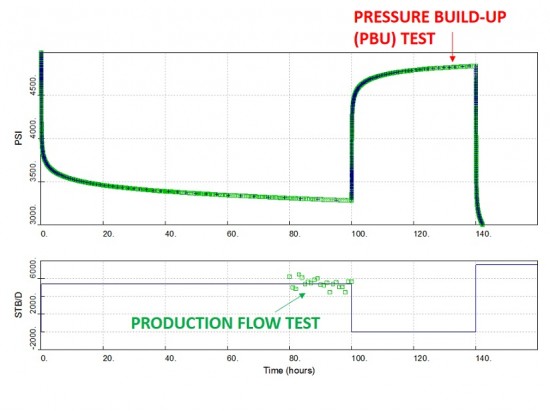

The figure below shows a well test in Exploration and Appraisal starting with a well clean-up, 2 pressure build-up tests and a main flow period.

An exploration and appraisal well test is used to confirm an oil/gas reservoir discovery, well productivity, pressure, reservoir heterogeneities and boundaries, hydrocarbon volumes, etc… Bottom-hole fluid samples are also taken for PVT laboratory analysis. This test will help to design a better development plan and production facilities to optimize recovery, while drilling less appraisal wells.

In a production context, a well test is performed when the well has a stable flow and is then quickly slam shut with the wing valve for a period of time. Pressure will build-up in the well and a PBU test will be available.

It is better to perform the shut-in when the well is flowing at a stable -and preferably known- flow rate. In addition, the production choke should not be used so as to avoid a slow shut-in.

A slow shut-in with the production choke will bring some uncertainty on the analysis rate, create a large wellbore storage that could mask some of the well and reservoir responses, or trigger wellbore phase redistribution that could corrupt the entire PBU test.

Initial PBU test in production

In addition to initial reservoir pressure data, the initial well test (or PBU test) in the above figure will provide information on connectivity, average permeability-thickness (KH) and reservoir features over thousands of feet in the reservoir, initial damage (skin) after drilling and completing the well. These results should be reviewed in the post well review to assess the completion performance.

To save costs, a new production well could only be cleaned up with the rig and the PBU test could then be performed in the first weeks of production, once the well is hooked up to the production facilities.

Why performing well tests / PBU tests in production ?

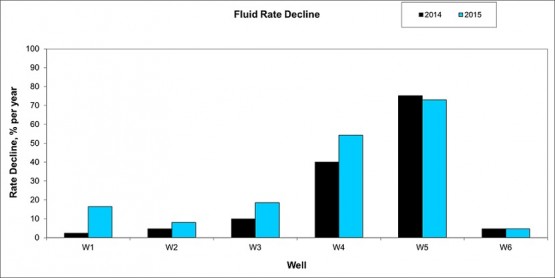

Knowing the rate data for each production well is the basics and a stable production flow test should be ideally performed once a month. Then the well performance could be monitored with the changes in the rate of decline.

A change in decline rate may be caused by a change in wellbore damage (skin), a change in flow behaviour, a reduction in effective permeability, or/and some problems with pressure support. This would be understood by a combination of well testing and production logging (PLT).

A PLT will help to understand the well conformance and any multiphase flow in the wellbore. However, it is often not run in production due to various reasons, including costs.

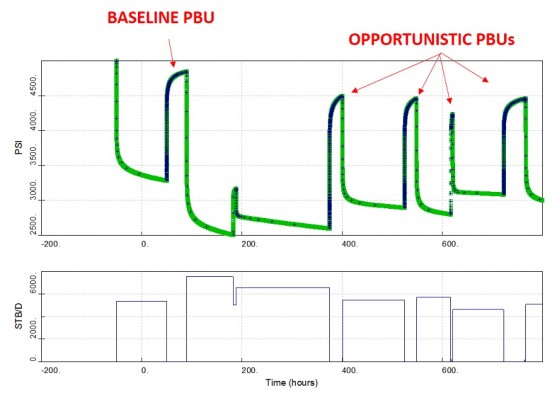

Anytime the well is shut-in, the pressure will build up and a “free” well test will be acquired. These opportunistic PBU tests will help to monitor production, diagnose any problem and maximize the well’s production life.

Being pro-active with production well tests can help to detect a production problem before it is detected at surface and before the problem becomes irreversible.

Even if there are multiple well tests without production flow tests, these could still be valuable to protect the oil and gas base production.

Recommendations

An initial production flow test followed by a PBU test is recommended for any new well. This helps to obtain initial pressure and an initial reference PBU which can later be used to understand changes in decline rate. The PBU test needs to be long enough to achieve radial flow regime.

It is recommended to have a good quality PBU once a month or quarter to monitor the well and reservoir performance and understand production decline. With permanent downhole gauges, more than 95% of the PBU tests (or production well tests) will be opportunistic, i.e. unplanned. These could be considered as “free” data and valuable subsurface information.

I thank you very much for everything you have done in the field of well testing

Great Article!!

The importance of a baseline PBU during start-up can’t be overemphasized. However, this is an idealised scenario where everything is working. In situations where your DHPG fail even before start-up, what do you do? resort to WHG? how uncertain is this scenario? do you defer PBU at SU to fix the gauge or go ahead to get this baseline data?