To test or not to test? This is a common question these days…

What are the worst possible nightmares in production?

That the production wells quickly decline after start-up? Or to produce H2S or some other fluid contaminants when the new plant is not designed to handle it? What if the water injection wells are not efficient, leading to a strong depletion and low recovery? I wouln’t like to be the new manager in this situation, probably not in the right place at the right time…

Could this be foreseen and avoided? Yes, it could have been with well testing…

With the trend of cutting costs, it is difficult to find some evidence to perform a well test at the Exploration and Appraisal stage. Even when the company will end up drilling less appraisal wells, remove the risk of a production train-wreck, and improve the recovery factor.

It seems that short term gains have the priority over long term value.

Well Testing isn’t very popular…

First, it involves some complex well test design and analysis using some derivatives, deconvolution, etc… Since the completion and reservoir engineers from operators do not tend to perform well testing on a routine basis, they tend to lack some experience in this area and sometimes have to “re-invent the wheel”.

There are some safety risks in operations, in particular if there are some lapses in expertise and processes, etc. Without proper expertise, the operator may open up the well too fast, over-pressuring or over-flooding the tanks. There is also an environmental factor, with risk of spills when cleaning up the well. In addition, the operator flares the hydrocarbon, which represents a small percent of the total rig operational emissions. This could be further reduced with technology and analysis techniques.

Finally, well testing involves some expensive operations in Exploration and Appraisal. Costs can quickly rise up with limited well testing experience, uninterpretable short test or too long operations. With expertise and new tech, the test could be optimized with much reduction in costs and flaring.

Why testing when permeability is available from static data (log derived permeability or core permeability)?

This is a fair and common question from explorationists, geologists and managers.

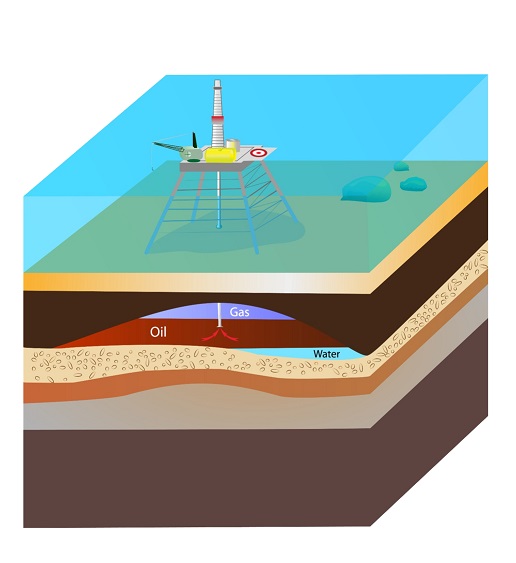

Static data are from a very localized area, less than a foot in the reservoir. It is likely not to be representative of the properties over thousands of feet away from the well. In addition, the flow dynamic behaviour may be very different to the expectations from the static description.

Reducing well testing to a permeability measurement is also restrictive. Well testing confirms that the well can flow at a sustained commercial rate. It gives the operator a (more accurate) reservoir pressure value, the different elements of well damage, rate-adding opportunities, reservoir heterogeneities, boundaries (seismic may not spot the critical sealing faults) and connected volumes. Large and representative fluid samples are acquired and help to reduce the uncertainty on the fluid properties and flow assurance.

Well Test Alternatives

As for the dynamic data, well test alternatives are back in fashion with low oil prices. Similar well test analysis techniques are used to interpret the results.

Water injection tests are quite useful for tight reservoirs and unconventionals. For conventional reservoirs, these tests create some complexity with fracturing and multiphase flow in the reservoir. Sometimes they work and give results similar to conventional well testing, sometimes they are not reliable.

Closed chamber tests, slug tests, downhole flow tests, mini-DSTs could be used as alternatives and some companies are leaders in these. After all, these tests give us what we want: permeability (even vertical permeability!), a measure of skin, some vertical heterogeneity (which may or may not be representative further away from the well).

These tests are more environmentally friendly (and help to reduce some few percent of the rig emissions), but above all cost effective to obtain a permeability and a skin value.