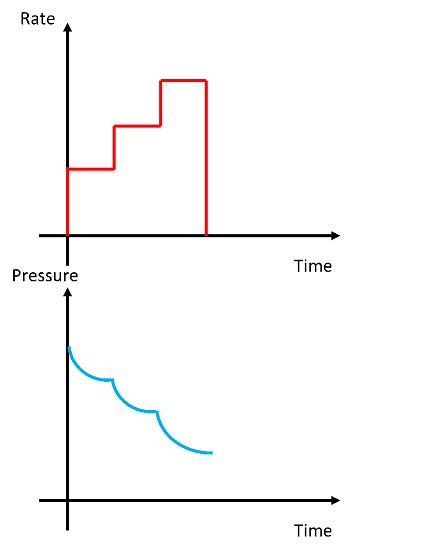

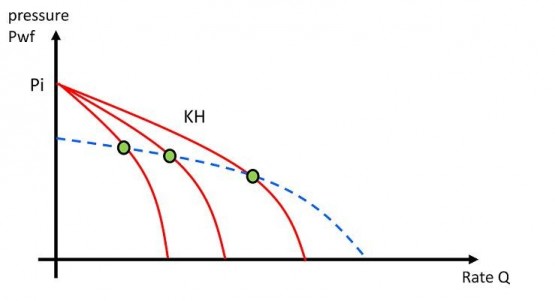

A transient IPR will change over time, as indicated with the different plots in red. Under transient behaviour, the risk is to assume that the several flowing points are under pseudo-steady state and on the same stabilized IPR. This will lead into erroneous reservoir pressure, KH and skin.

As a matter of fact, the skin can only be derived from a PBU analysis.

Reservoir performance from PBU analysis

Some few flowing pressure points and rate data do not define the productivity of a well, especially under transient behaviour. It will be misleading and will result in wrong KH, skin, reservoir pressure, and hydrocarbon volume.

The well and reservoir performance should be derived from well test analysis on several PBUs.

Everything can be obtained from 2 PBU tests: permeability and skin, the different skin elements, initial pressure, heterogeneities, hydrocarbon volume, distances to the boundaries, etc… All this information can then be used to build the IPR, for example.

In a well test design study, you should forget about adding a complex deliverability test but focus on two PBU tests and make sure the shut-ins are long enough to derive a reliable deconvolution.

Short step rate test to obtain the non-darcy skin

More (reliable) information is extracted from PBU analysis than from any deliverability test. The only test that you should be interested in is a simple increasing step rate test for gas and gas condensate wells.

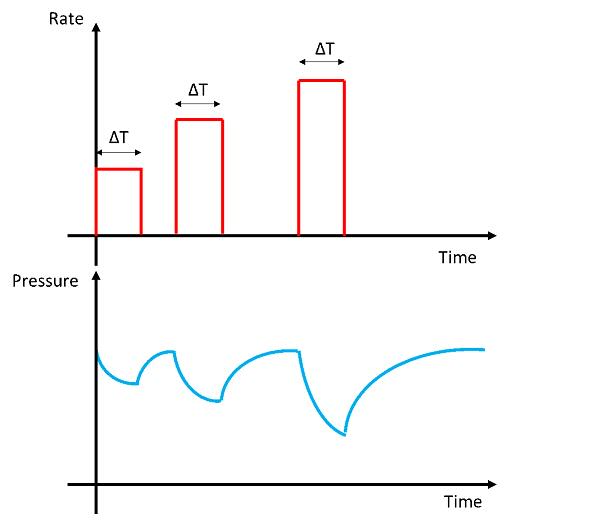

This is different from the flow-after-flow test because we don’t need to wait for pseudo-steady state. We only need to flow for a couple of hours and make sure that radial flow regime is at least reached for each step (and not dominated by wellbore storage effects).

This test is not to define the inflow performance relationship (IPR), but to extract the turbulence (or non-darcy skin element). As a consequence, the criteria shouldn’t be to wait for pseudo-steady state and the test can be shortened to a couple of hours.

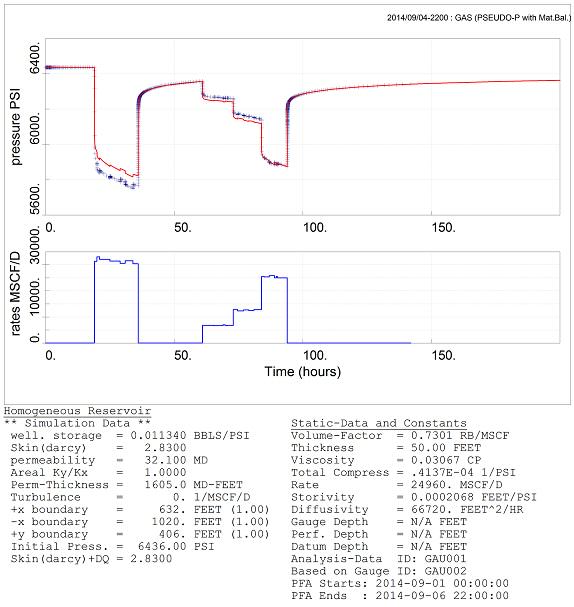

In the well test analysis workflow, we first need to match all the PBUs, as shown below.

(It is worth noticing the “depletion” trend in the PBUs. This doesn’t mean that the reservoir is closed and reservoir pressure changes. In this case, it only supports the presence of boundaries).

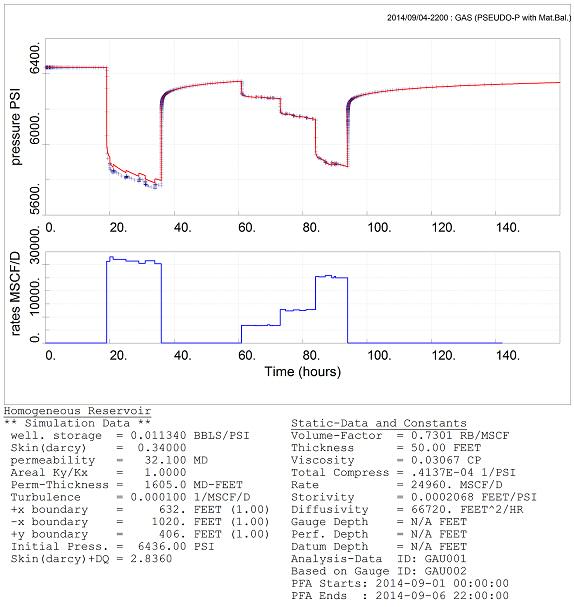

Once all the PBUs are matched, the user can match the short step rate test by tweaking the non-darcy skin.

By increasing the turbulence factor while decreasing the mechanical skin to keep the total skin constant, we obtain a match on the deliverability test.

The first flow period from 20 to 40 hours cannot be matched and shows that the skin in our model is too low during that period. In reality, the actual skin was larger at the beginning of the test and the well is slightly cleaning up.

Some well test softwares, such as Saphir and PIE, offer an option to automatically calculate the non-darcy skin based on the short step rate test.

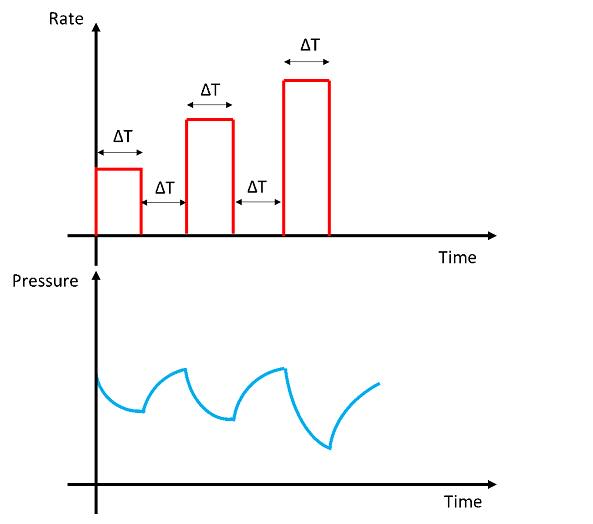

Step rate test can be dominated by wellbore dynamic effects and not be representative of the well and reservoir.

Several flow periods in the step rate test can be dominated by a changing fluid density below the gauge. We need to place the pressure gauge as close as possible to the perforations and be cautious when matching the test.

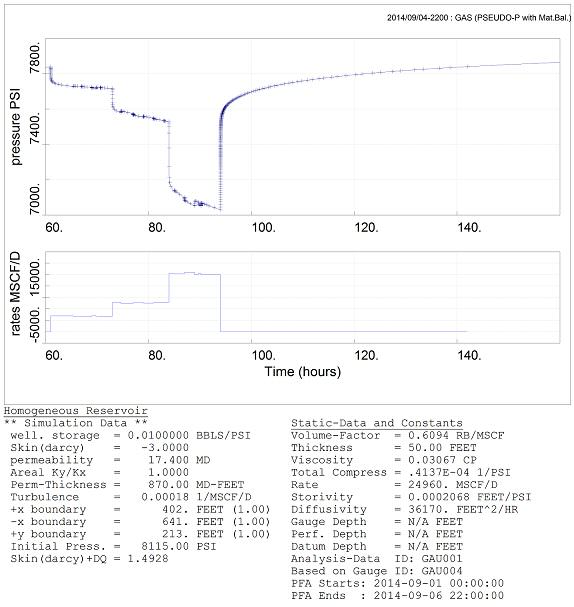

After a well test analysis, your model should match the several PBUs and the step rate test, as shown below.

But in this particular case with a vertical well, the total skin is about 1.5 while the mechanical skin is about -3. This is a red flag that the step rate test is not reliable and the data are affected by some dynamic effects in the wellbore.

This is probably because the two first flow periods are affected by a different fluid density below the gauge.

The turbulence factor that is derived from this analysis won’t be correct and will be over-estimated.

As the fluid density below the gauge changes during each step, you should not expect to match all the 3 rate steps with one value of non-darcy skin. This deliverability test cannot be used.

For more information or for a discussion on this topic, please don’t hesitate to contact us.

Hi. Thanks for the post, very useful and informative.

With PBU we will get all the parameters required for IPR using either RS/Jones method or LIT method. But, here we need to assume drainage radius again, how to find that one using PBU?