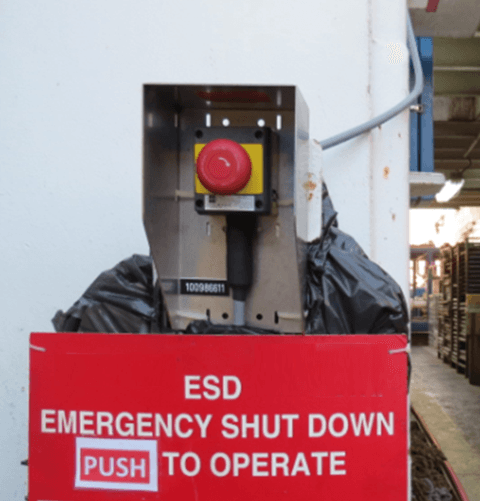

Would you push the Emergency Shutdown button ?

Risk assessments, procedures, planning, training, safety systems, etc… All are in place to make sure that the operations are safe. But on some circumstances, you might have to push the ESD (Emergency Shut Down) button.

“If something seems or looks unsafe, push the ESD button”. This is clear and understood by everybody. (Most) companies have a safety culture and in an unsafe situation, the job needs to be stopped immediately.

In a well test operation, in case of a clear safety issue such as an accidental release of hydrocarbon or the presence of a source of ignition, you will push the ESD button. In emergency situations, the first step to do is to raise the alarm and then escape via emergency routes.

But what about more subtle cases ? What about proactively stopping the operations, before any clear emergency situations ? If during the operations, something does no longer make sense or you think that something appears unsafe, then it may not be easy to push the ESD button, and you may wait too long. Although the company has a safety culture, although the actions to take in case of emergency are discussed beforehand, you may still be uncomfortable pushing the ESD button in case of “doubt”.

If you are a junior, if it is your first trip offshore and you see someone (let’s say someone grumpy) with 30+ years of experience doing something that you may think unsafe, would you stop him and stop the operations?

It is not an easy task… why ?

There might be some different reasons:

No sufficient training and sharing among companies

Someone may not push the ESD button simply because he or she may not spot the safety issue or has some doubt about the potential risk and consequences.

An HAZOP study conducted during the planning phase will provide a review of the safety system and any person involved in the operations should be welcome to attend the study. Still, people may not be sufficiently and/or frequently trained and may not be looking at the right trends during operations. An inaction or delay may cause the issue to escalate and to become a serious threat.

Near misses and incidents are no longer shared between companies, and remain “confidential” as if it is a trade secret, perhaps a competitive edge, or perhaps an evidence of the company’s bad performance. Why hiding something that could save lives ?

If you work for British Airways, and Air France had a problem with a particular process or piece of equipment, won’t you like to make sure that this doesn’t happen again across all the aviation industry? It should be the same with the oil industry. Anything that can prevent any incident should be shared.

Experience / behaviour

Even when sharing a potential safety issue between companies, some may think that this won’t apply to them, that they have the best people, the best procedures, the best processes, etc… Experience, years of routine and successful operations might bring high self-confidence and ego.

Repeating a process or doing something over and over doesn’t make it safe. If you have done something a hundred times, does it mean it is safe to do it ? You may be a hundred times lucky, or a condition may have changed and the routine procedures or actions no longer apply or are no longer safe. Previous successes don’t make future successes. Self-confidence or ego may blind you or make it difficult (or painful) to recognize that you are wrong, that something unsafe hasn’t been spot. Perhaps in this case, pushing the ESD button could be seen as a failure.

A continuous reassessment of yourself, of risks, of processes, procedures is needed. Repeated training and simulating case scenarios are needed along with experience.

This is your safety. As often the case in the oil and gas industry, experience doesn’t necessarily mean expertise. As a young graduate may think during operations: “if the experienced people around me don’t view the situation as unsafe, while would I – a young graduate fresh out of college- push the ESD button ?”

The role of experienced people is also to make others feel comfortable to take the lead and push the ESD button in case of unsafe observations.

Fear of failure

Pushing the ESD may be seen as a bad news, the job didn’t go as planned and as smooth as it could, with now some delays in the operations. The emergency shut-down may be wrongly seen as a sort of failure. It is the contrary !

Pushing the ESD button is a success, in any event. The person and the team successfully spot a potential ops issue among all the rig activities and took action to prevent this issue to escalate. They showed courage and safety values. Even in case of doubt or in case of a “false alarm”. The failure will have been not to push the ESD button, potentially leading to a catastrophic situation.

Pushing the ESD button takes courage and leadership. We see this as a complete success to spot something potentially unsafe, take action and prevent any escalation.

Cost culture

For (most) companies, the safety culture is the number 1 priority. But unfortunately, the cost culture is still strong, especially with increasing rig cost. A common expression in the industry is to minimize risks as “reasonably” as possible. But the word “reasonably” already means it has to be at a certain cost. And sometimes, we accept the risks.

The surface safety valve is connected pneumatically to a safety system. Pushing/pulling the ESD button relieves the pressure in the safety system and the surface safety valve is automatically shut-in. Operations are stopped. The team need to spend time to understand the problem, discuss it, find a solution, check the lines and re-start slowly the operations. Of course, all these steps take time, perhaps a couple of hours or more, and therefore money, with the rig sitting still. If the operations are already delayed, if the daily rig cost is very high, then the management team who may be too focused on the cost analysis Excel spreadsheet, may start to stress and require some explanations.

Under pressure, under uncertainty, under doubt, the spectre of the cost culture and rig cost makes it challenging for the brave person onboard to push the red button. However, not activating the ESD button could lead to dangerous situations with near-misses or incidents, with a much longer shut-in period. In the worst case scenario: a disaster with loss of lives, loss of equipments, and in terms that a company with a strong cost culture may understand: huge financial losses, bad reputation and loss of business. This was the case for Piper-Alpha. Since then, some other companies came near collapse.

Some major incidents in the industry are viewed as a combination of factors, but bad behaviour created by a cost culture is certainly a significant one. The operations could be proactively stopped and discussed at any time. Always.

The long term consequence of not pushing the ESD button in case of doubt certainly exceed the short term gain of a couple of hours.

Fear of criticism

In case of doubt, one may not activate the ESD button for fear of being criticized or judged. There is the fear of being the one that doesn’t fully understand what’s going on, or the one being over-cautious, or the one not being “reasonable”, etc…

Pushing the ESD button in case of doubt, before an incident occurs, is not being over cautious, or being the one that doesn’t understand, it is about acting as a leader. It is about being proactive, taking all the precautions to ensure your safety and that of the people around you.

People with experience should always ask the quiet person to freely express her opinions (and preferably outside the group).

Fear of retaliation

There is a common expression: “kill the messenger”. Some still don’t like to hear bad news, and tend to “kill the messenger” of bad news. Perhaps, as a result, people don’t want to create or communicate bad news, and may do all the wrong things so as to delay the bad news.

Not activating the ESD could be a way to avoid or delay bad news to the client or to the boss. You should welcome bad news especially in exploration and appraisal context. It is always better (and safer) to find out something is wrong early on.

Try to be inquisitive in operations and act as a safety leader, independent of your role and responsibilities. And when you think something is unsafe, automatically push the ESD button. If anything else, this will result in a nice PBU test with a hard shut-in for a couple of hours that will bring some valuable subsurface data.

Did you ever come up with an emergency shut-down ? did you think this was a failure or a success in operations ? Don’t hesitate to contribute with your experience about ESDs.

For more information or for a discussion, please don’t hesitate to contact us.