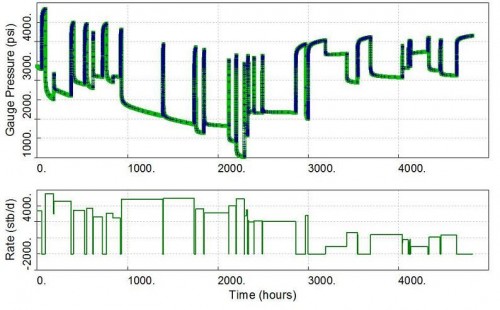

Every PBU, every PFO, every shut-in contain some critical information about your well and your reservoir.

Every shut-in is an “information snapshot” of your well and reservoir.

Do you use every production shut-in as an opportunity to learn?

Do you have the resources and expertise to do this for each of your wells?

Thanks to downhole gauges, about 95% of production PBU tests should come from opportunistic shut-ins. Do you analyze and extract information from all these “free” PBU tests ?

Why analyzing production shut-ins ?

Baseline initial PBU tests help to define the initial well performance and to assess completion performance in a post well review. It is worth mentioning that due to the transient response, a combination of rate and pressure measurement points doesn’t define well productivity, in particular for a vertical well in low-mid permeability reservoir, a fractured well or a horizontal well.

Opportunistic production shut-ins are a great surveillance and diagnostic tool. Analysis of these “free” data helps you to monitor and predict well and reservoir performance over time, to QC the rate measurement and the allocation process, to detect and understand performance deviation and assess the true impact of a well intervention.

We can help you !

We can help you to establish surveillance best practices and test procedures so that you can obtain the best quality valuable shut-ins during production.

For a new well delivery, we can help to provide justification for downhole gauges (also in water injectors), to ensure your data processing system is adapted to pressure transient analysis and to design your planned shut-ins.

We can have a look at your shut-ins, help you monitor well performance over time, track reservoir pressure and perform multiphase flow analysis. We will be in a good position to detect and understand well performance deviation and give you recommendations on data acquisition during a well intervention.